Selecting appropriate structural steel is crucial for project success, safety, and long-term performance. With numerous grades, types, and specifications available, making the right choice requires understanding both your project requirements and material properties.

Understanding Steel Classifications

Structural steel is classified by various standards including ASTM (American Society for Testing and Materials), EN (European Norms), and JIS (Japanese Industrial Standards). Each classification defines specific mechanical properties, chemical composition, and performance characteristics.

Common ASTM Grades:

- ASTM A36: Most widely used structural steel with yield strength of 36,000 PSI, ideal for general construction

- ASTM A572 Grade 50: Higher strength steel with yield strength of 50,000 PSI, suitable for heavy-duty applications

- ASTM A588: Weather-resistant steel that forms a protective oxide coating, reducing maintenance requirements

Project-Specific Considerations

Environmental Factors: The operating environment significantly impacts steel selection. Marine environments require corrosion-resistant grades like 316L stainless steel or weathering steel. Chemical processing facilities need materials that resist specific corrosive agents.

Load Requirements: Understanding both static and dynamic loads is essential. High-tensile steel grades like S355 or ASTM A572 Grade 50 are necessary for applications with significant structural loads or seismic considerations.

Temperature Considerations: Extreme temperatures affect steel performance. Cryogenic applications require special low-temperature steel grades, while high-temperature environments need heat-resistant alloys.

Steel Product Selection Guide

For Building Construction:

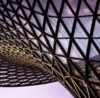

- Beams: I-beams and H-beams provide excellent strength-to-weight ratios

- Columns: Wide flange beams or structural tubes offer superior load-bearing capacity

- Connections: Angle irons and channel sections ensure proper structural connections

For Industrial Applications:

- Platforms: Checker plates provide anti-slip surfaces for safety

- Tanks: Plate steel with appropriate thickness and corrosion resistance

- Piping Support: Structural angles and channels for proper support systems

For Specialized Applications:

- Wear Plates: HARDOX or AR400/500 grades for abrasive environments

- Precision Components: Bright steel bars for machined parts

- Reinforcement: Deformed bars (rebar) for concrete reinforcement

Quality Assurance and Certification

Always verify that steel products come with proper mill test certificates (MTCs) that document:

- Chemical composition analysis

- Mechanical property test results

- Heat treatment records

- Dimensional specifications

Third-party inspection services can provide additional quality assurance for critical applications.

Cost Optimization Strategies

Material Efficiency: Optimize designs to use standard sizes and reduce waste. Custom sizes often carry premium pricing and longer lead times.

Grade Selection: Don’t over-specify materials. Using higher grades than necessary increases costs without providing additional value.

Supply Chain Consideration: Work with suppliers who maintain inventory of common grades and sizes to reduce lead times and emergency procurement costs.

Conclusion: Proper steel selection requires balancing performance requirements, environmental conditions, and budget constraints. At Polar Industrial Solution, our technical team provides expert guidance to help you select the optimal steel products for your specific applications, ensuring project success while optimizing costs.